Technical Resources & Insights

Expert articles, engineering guides, and industry news to help you optimize your operations.

Understanding IE3 and IE4 Efficiency Standards in India

Decode the IS 12615 standards and learn how upgrading to IE3/IE4 motors can drastically reduce electricity bills for Indian industries.

Industrial Motor Maintenance Checklist for High-Temperature Environments

Indian summers can be harsh on machinery. Follow this essential maintenance guide to prevent overheating and breakdown during peak production months.

Choosing the Right Motor: Foot vs Flange Mounting Guide

B3, B5, or B14? Decoding mounting standards to help you order the perfect fit for your pumps, gearboxes, and compressors.

Preventing Common Motor Failures: A Root Cause Analysis

Why do motors fail? From bearing currents to single-phasing, we analyze the top 5 killers of electric motors and how to stop them.

The Copper Rush of 2026: Why 'Dr. Copper' is Suddenly the Most Expensive Consultant in the Room

Copper prices have smashed through $13,000/tonne, driven by an AI data center boom and green energy demands. Explore why the world is facing a 'Scarcity Premium' on its most vital metal.

The Anti-Gravity Machines: How Lifts and Cranes Are Getting a 'Brain Transplant'

Your apartment building is a machine. From the crane that built it to the lift that carries you, the motors are changing. Goodbye gears, hello magnets.

Our Precised

Engineering Products

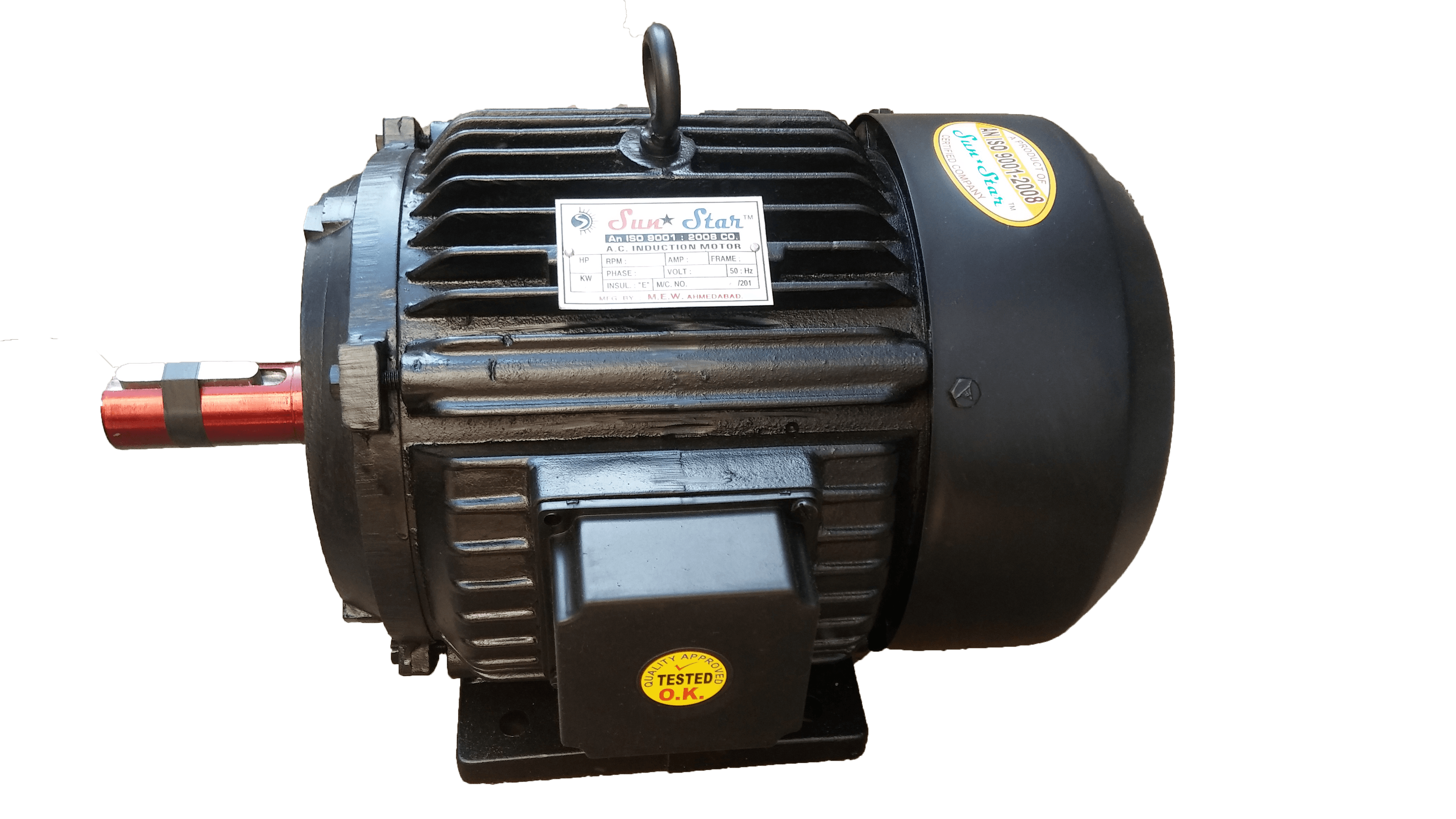

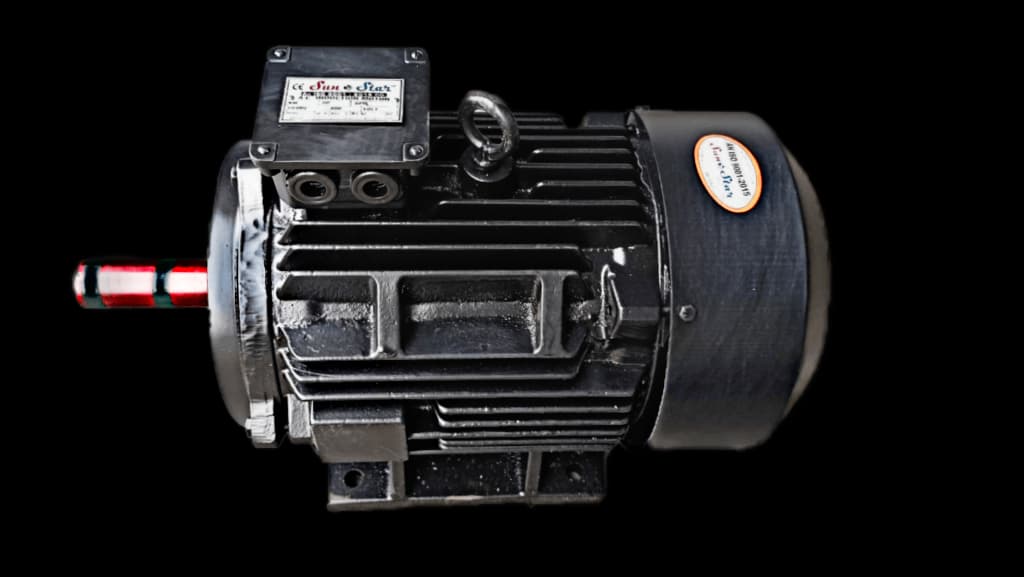

Standard Motor

A standard motor is a basic motor used for a variety of industrial applications such as conveyors, compressors, pumps, and fans. It is a single-phase or three-phase induction motor that operates on AC power. This type of motor is highly efficient, reliable, and cost-effective. Some of the features of a standard motor include high starting torque, low noise, and easy maintenance.

Brake Motor

A brake motor is an electric motor equipped with a braking system that can stop the motor quickly and safely. This type of motor is commonly used in industrial applications where safety is a concern, such as conveyor systems and cranes. The brake system helps to prevent accidents and equipment damage. Some features of a brake motor include adjustable brake torque, low power consumption, and low maintenance.

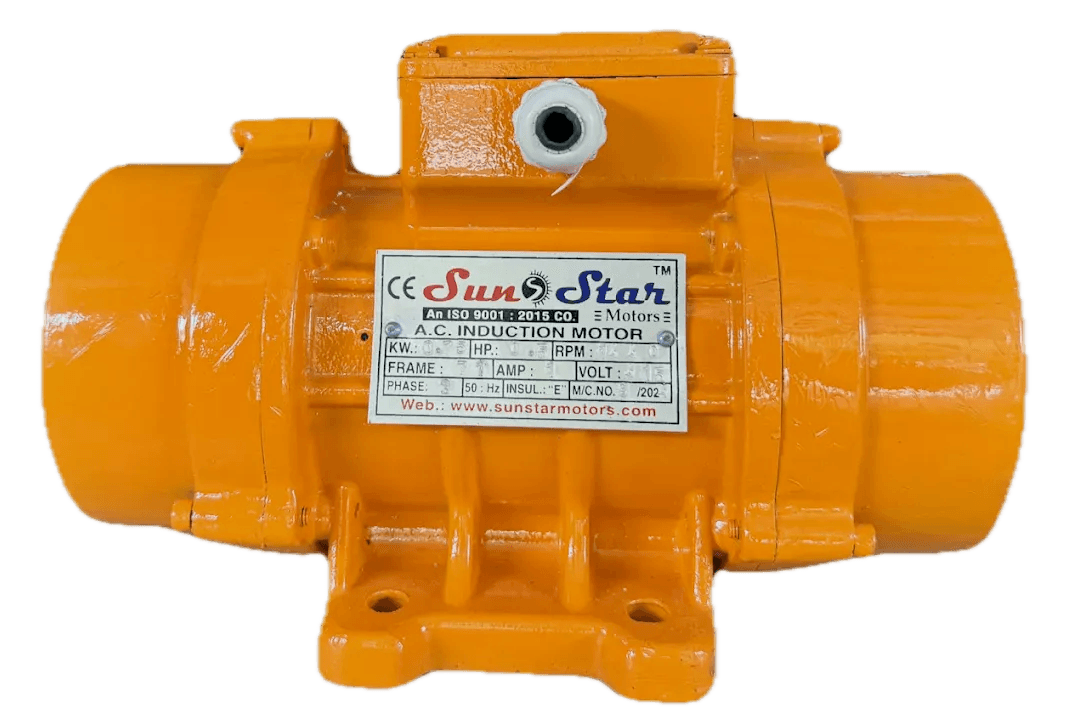

Vibrator Motor

A vibrator motor is a specialized motor used to vibrate equipment and machinery, such as vibrating screens, feeders, and compactors. The vibration can help to move and sort materials, compact soil, and reduce air voids in concrete. Some features of a vibrator motor include adjustable vibration frequency and amplitude, low noise, and high efficiency.

Cooling Tower Motor

A cooling tower motor is a motor used to circulate water through a cooling tower to cool down the water and remove heat from the system. This type of motor is commonly used in industrial applications where heat removal is a concern, such as in power plants and manufacturing facilities. Some features of a cooling tower motor include high torque, high efficiency, and durable construction.

Heavy Duty Motor

A heavy-duty motor is a powerful motor designed to handle high loads and extreme conditions. This type of motor is used in industrial applications such as cranes, hoists, and mining equipment. Some features of a heavy-duty motor include high torque, high efficiency, and durable construction.

Stay Ahead of the Curve

Subscribe to our technical newsletter for the latest engineering updates and product announcements directly to your inbox.